闸阀的结构分类有哪些?

Jun 04, 2022

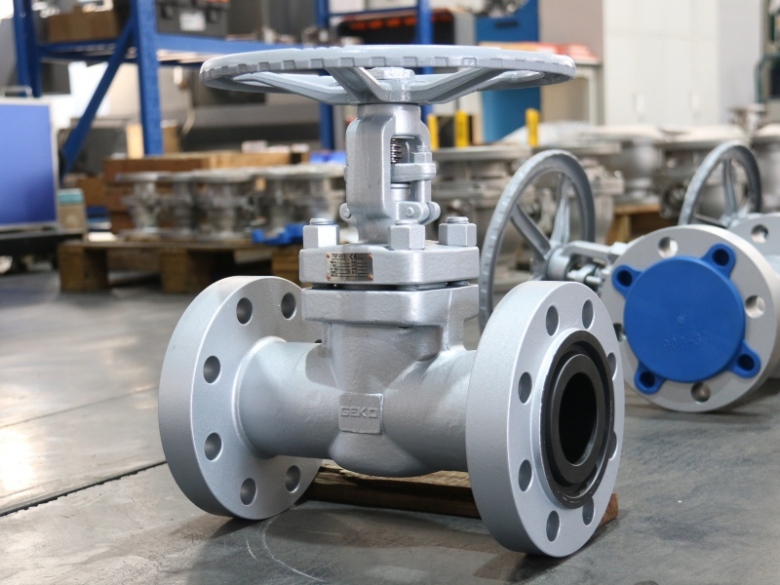

闸阀结构的分类方法有很多种,主要区别在于密封元件的结构形式不同。根据密封元件的结构,闸阀通常分为几种类型,最常见的闸阀类型是平行闸阀和楔形闸阀。根据阀杆的结构,闸阀还可以分为升杆式闸阀和暗杆式闸阀。 1. 并联闸阀 平行闸阀的两个密封面垂直于管道轴线,即两个密封面彼此平行的闸阀。在平行闸阀中,带推力楔的结构最为常见,适用于低压、中小口径的阀门。弹簧可以产生必要的预压缩力,有利于闸板的密封。此外,还有通过机械装置(如杠杆、螺杆机构等)推动闸板开启的平行闸阀,以及仅有一对密封件的单向平行闸阀。这些结构目前仅在特殊工况下使用。 2.楔形闸阀 楔形闸阀的两个密封面与管道轴线形成一定角度,即两个密封面呈楔形的闸阀。倾斜角的大小主要取决于介质的温度。一般来说,工作温度越高,倾斜角就应该越大,以降低温度变化时闸板发生楔入的可能性。楔形闸阀可分为双闸板、单闸板和弹性闸板。 3. 升杆式闸阀 这种闸阀的阀杆螺母安装在阀盖或支架上。阀门开启和关闭时,通过旋转阀杆螺母来实现阀杆的升降。这种结构使得阀杆螺纹部分不与介质接触,不易被介质腐蚀,同时有利于阀杆螺纹部分的润滑,因此应用广泛。如需了解闸阀价格,请联系专业的闸阀供应商GEKO。 4. 深色阀杆闸阀 这种闸阀的阀杆螺母与阀体内的介质直接接触。阀门的开启和关闭是通过旋转阀杆实现的。这种结构的唯一优点是闸阀在开启和关闭过程中高度不变,因此 闸阀安装 空间虽小,但此类阀门必须配备开启和关闭指示器,以显示阀门的开启状态。 目前,在石油化工系统中,尤其是在长距离油气管道中,浮动阀座平闸阀得到了广泛应用。这种平闸阀具有流体阻力小、密封性能可靠、使用寿命长等优点。平闸阀分为带导孔和不带导孔两种类型。带导孔的平闸阀主要用于油气管道的管道清洗,而不带导孔的平闸阀则适用于各种管道的启闭装置。这种闸阀的制造工艺相对简单,易于实现自动化生产。

阅读更多